If you have read this blog you know I am trying to keep the old school feel of this project while making it more drivable since it is my daily driver. I had already replaced all the dash lights with LED bulbs in OEM green. This made the dash actually readable at night. At that time I also replaced the dome light which was broken. That came with an incandescent bulb which was fine but I replaced that bulb with an LED bulb to make it brighter. The prior owner tried to fix the original dome light (which was obvious due to all the tape and glue) but when he/she put it back together the door switches were no longer turning on the light when the door was open. I lived with this for a couple of years and just used the dome light as a manual turn on, but it was on my list of things to address at some point.

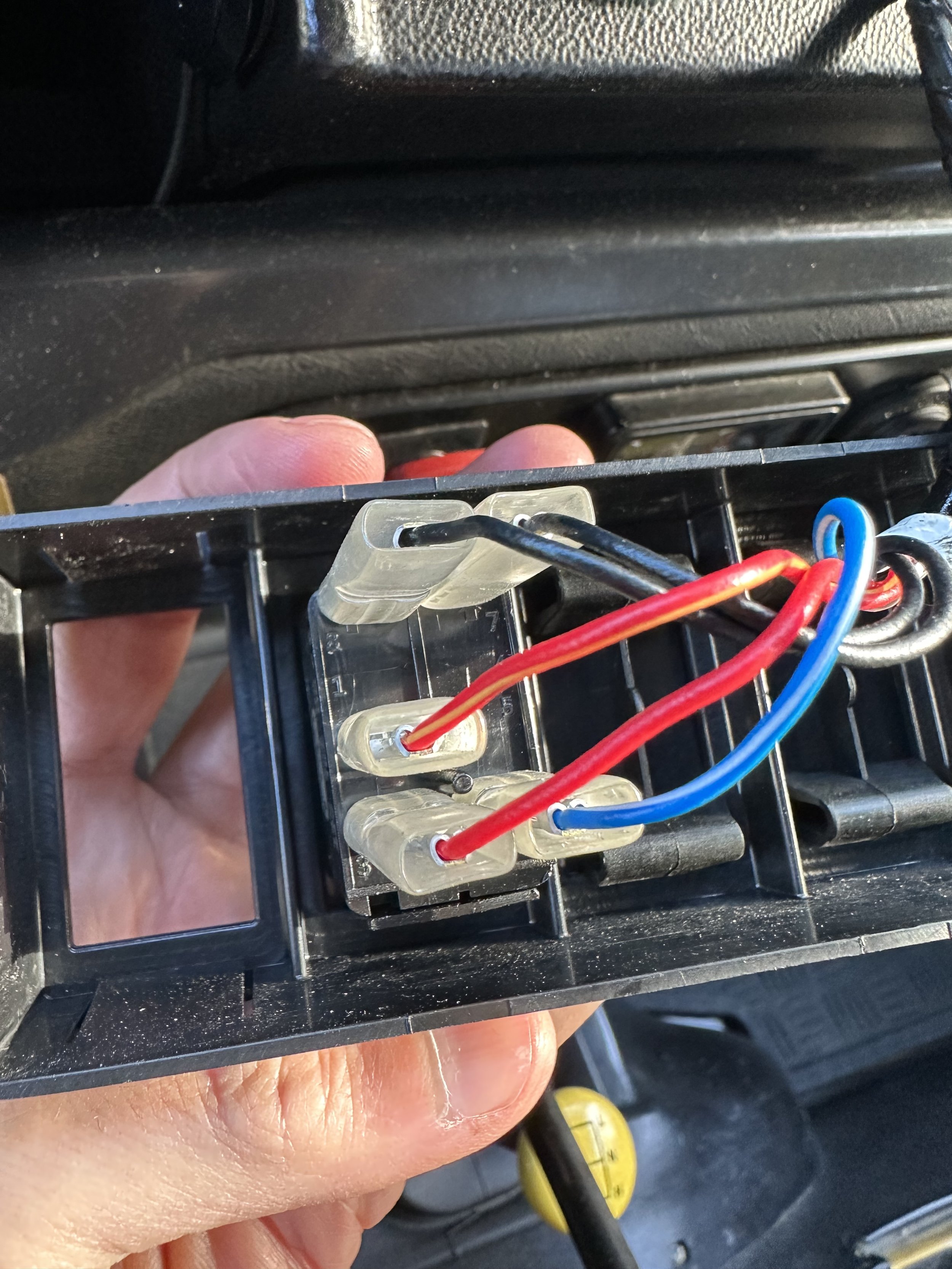

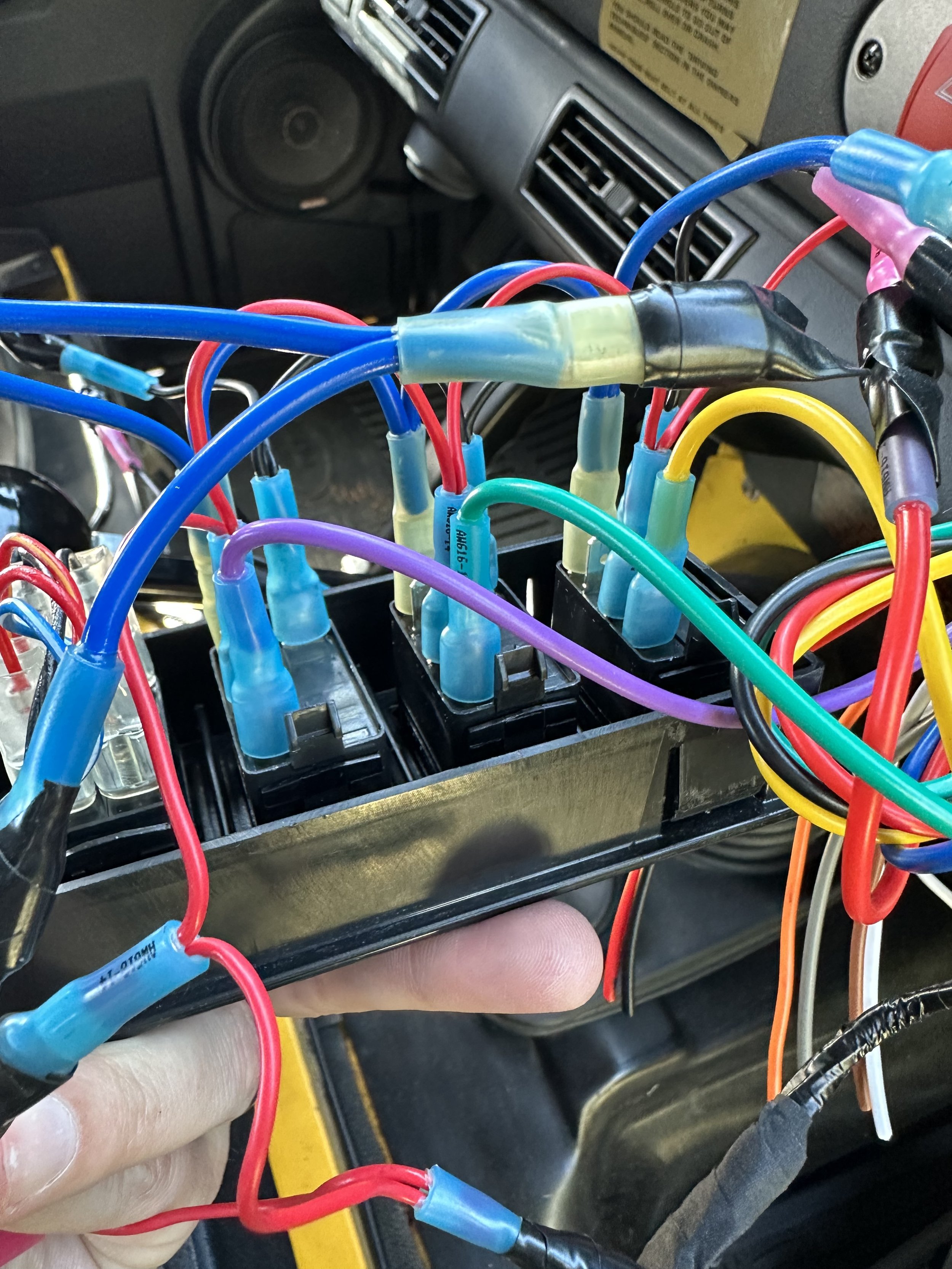

So on a lazy Saturday I decided to figure this out. The first thing was to ensure I understood the wiring. As it turns out there are three wires to the dome light (black = constant ground, purple = constant 12v, purple with a blue trace = door switches). The next thing was to understand how the door switches worked. They are actually ground switches not positive switches….meaning the door switches connect or break a ground to the chassis. The screw of the door switch creates a ground to the chassis but that ground is only passed through the wire when the shaft of the switch is not pressed in by the door. The ground wire from the passenger door switch runs to the driver door switch and then it runs to the dome light as the purple with blue trace wire.

With that understood, the next thing was to ensure the wires were hooked up properly to the dome light. Mine were not. It should be purple (constant 12v) plugged to the bulb body, dome light switch position 1 hooked up to the black (constant ground) wire, and the dome light switch position 2 hooked up to the purple with blue trace (door switch ground) wire. This way when you put the dome light switch in position 1 it will manually turn on, but when you put the dome light switch in position 2 it will turn on when either door is open.

In my case the light would come on with the manual switch but the door switches would still not turn on the light. Upon inspection of my door switches I notices they were corroded which is common with this design. I cleaned up the terminals and then everything worked. Since new door switches are only $20 I ordered two new ones to be safe. Now I have a fully functional dome light and with the LED bulb it is much brighter. With this fixed there is only one thing left in the entire car that is not working as it should and that is the driver seat belt warning light. So that is next on my list.