The Defender is not known for its storage, hell it only has one compartment to put anything in. I already fixed up the cubby box to make it functional again and I used the seat boxes for things like electrical gear and an air compressor. For trip gear I figured I would use soft bags tossed in the back but after a few day trips I realized I didn’t love my recovery gear or tools shifting around back there. I looked around and finally came across Mobile Storage Systems out of the UK. Like the name implies, they specialize in metal storage solutions for Land Rovers.

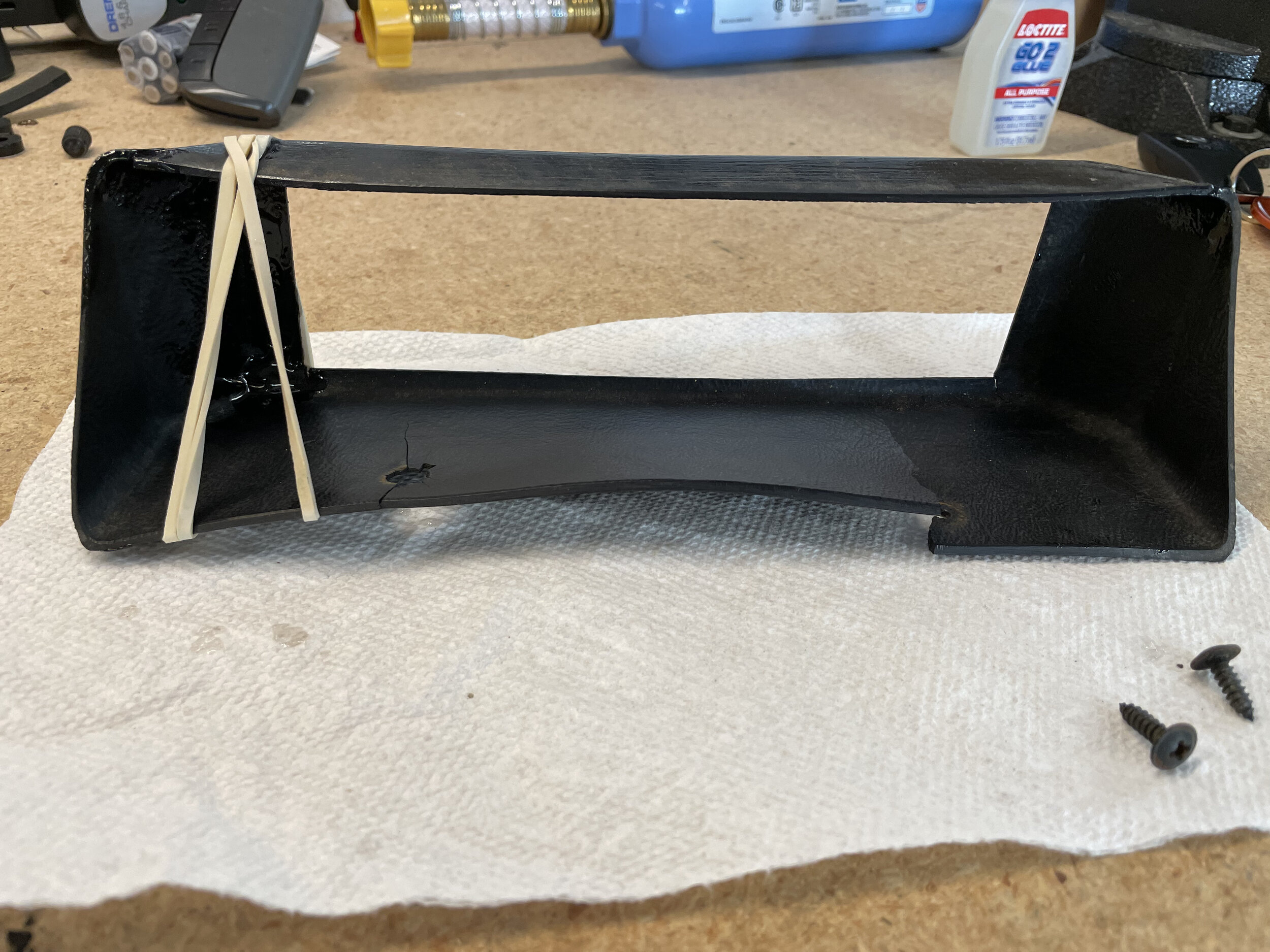

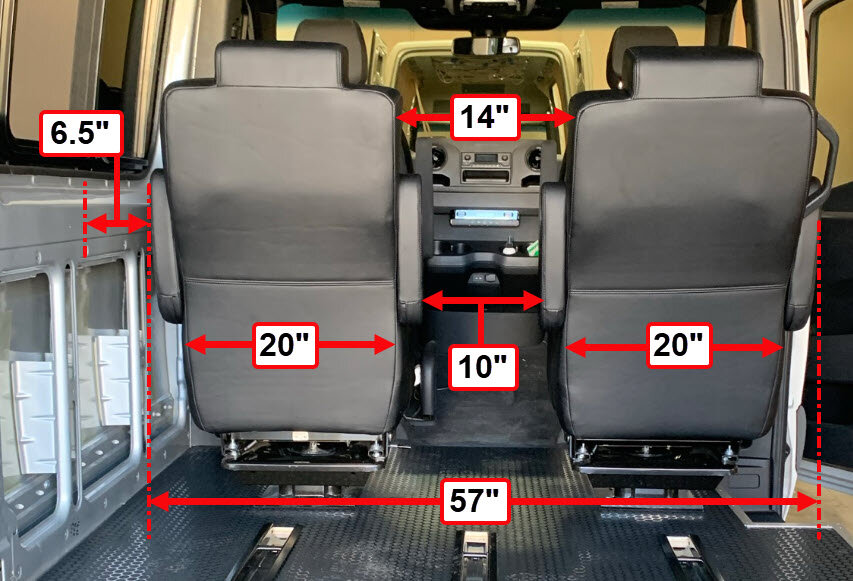

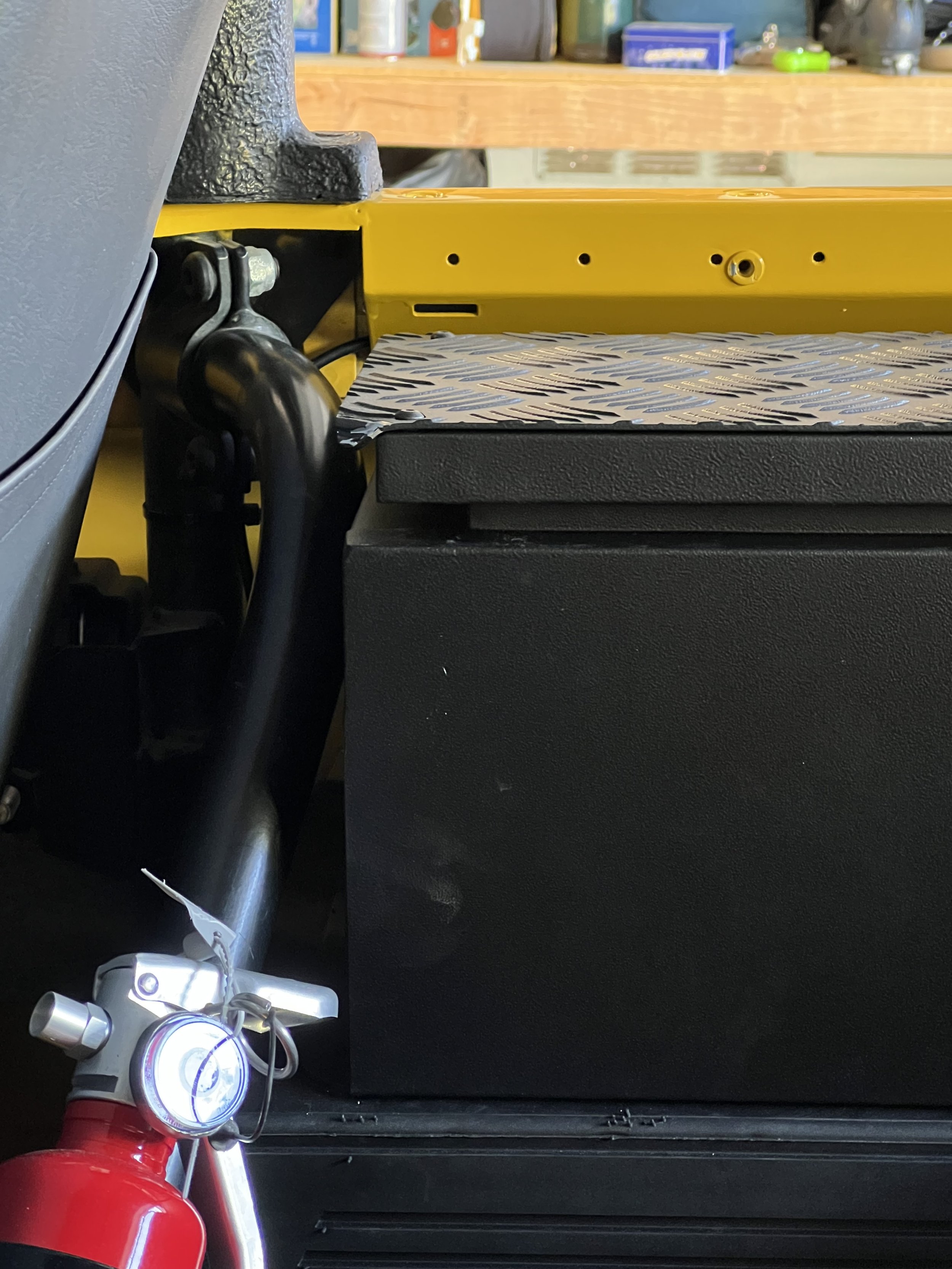

I decided to try out their wheel well locking storage boxes, of which they make a couple different sizes. My goal was to get as large of ones as I could to maximize the dead space above the wheel wells. As you may recall I removed the jump seats (as they are death traps) and installed an OEM bench which left the wheels wells open. Mobile Storage Systems makes a large box, a large box that fits around the fuel filler, and a small box. I determined I would get one large box for the driver side and a small box for the passenger. I did this because the fuel filler large box would not allow me to retain my rear speakers and Mobile Storage Systems said a normal large box would not fit on the passenger side of a NAS due to the smaller space between the fuel filler and the cross bars.

Once the large and micro boxes came I test fit them and found out that you can mount a large box on either side of a NAS but just barely. So I ordered a second large box and will sell the micro. With this storage capacity I will be able to permanently store my recovery gear and a set of tools. I also found that for the passengers in the back these boxes act as nice arm rests.

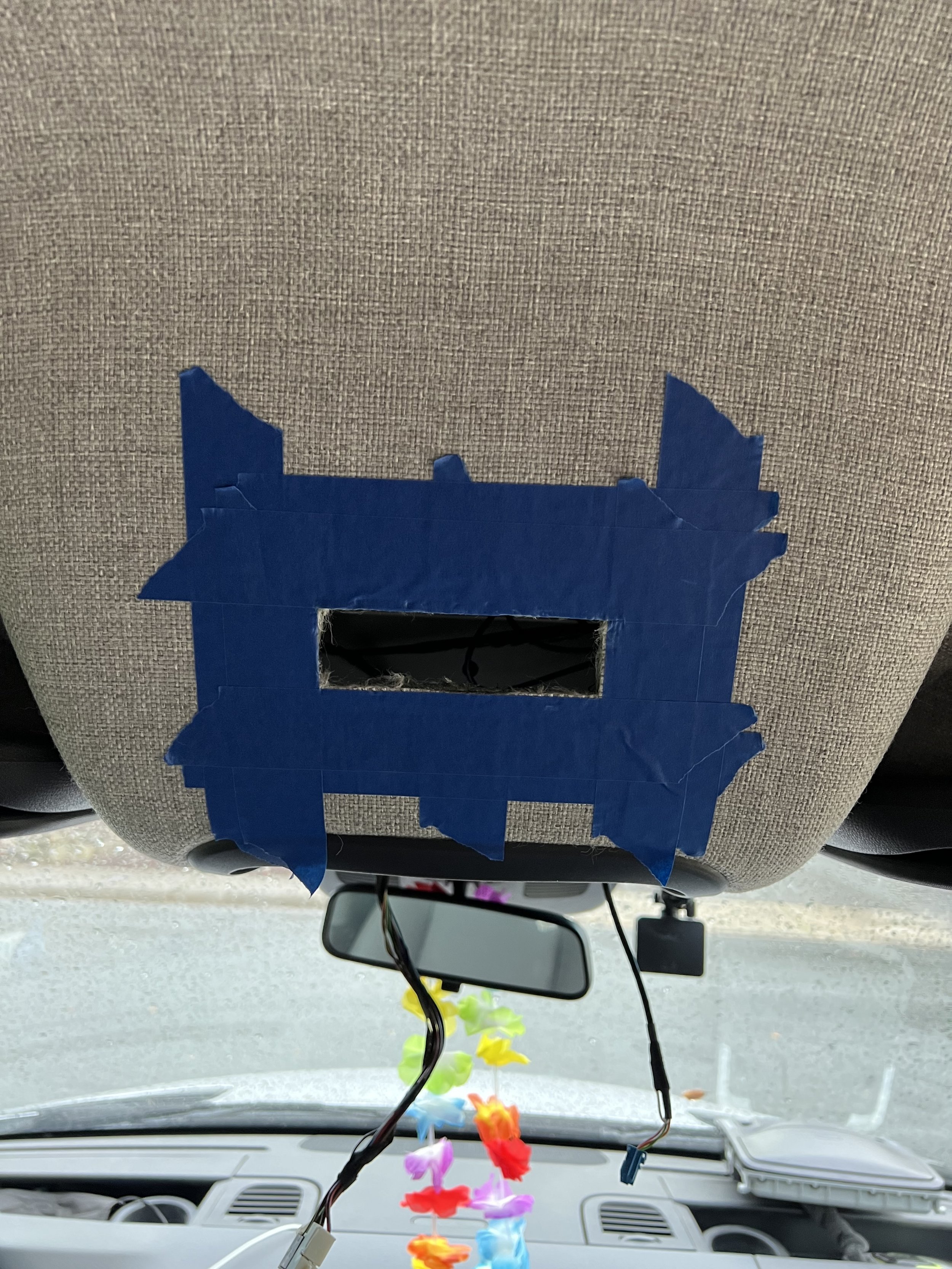

The install is straight forward. Each box has 6 bolts that go through the top of the wheel wells. I previously had bolt holes in the wheel well for the jump seats so while I was here drilling the appropriate holes for the storage boxes I filled all the unused holes with JB Weld. The lesson I learned is to make your wheel well holes larger than you need so that you can have some minor movement in order to line up the other bolts.